Fields of Application

for high temperature superconductor (HTS) applications

©Niklas Guenther via Canva.com

Despite the transition temperatures of "common" superconductor materials (e.g. Bi2Sr2Ca2Cu3O10 (BSCCO): 110 K and Y-Ba2Cu3O7 (YBCO): 92 K), which are now well above 4K, they still require cryocooling at preferably 20-30 K for the load case (at high currents), since the transition temperature is strongly dependent on the current conducted at the surface of the superconductor and the external magnetic field.

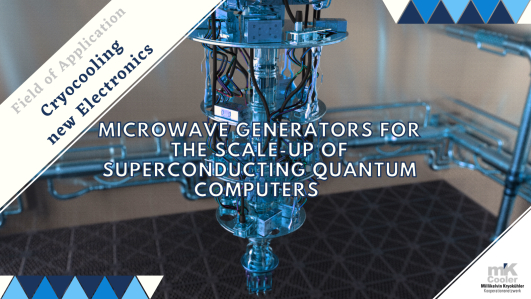

(such as microwave generators) for quantum computing

©Niklas Guenther via Canva.com

The cryocooling of new electronic elements, which is essential for the scale-up of superconducting quantum computers, is also to be considered. So far, 2 to 3 microwave conductors are still needed per QuBit for the control and readout of QuBits, which cause considerable effort and heat input.

Based on superconducting materials

©Niklas Guenther via Canva.com

The second field of application for the new mK-Coolers is the field of ultra-sensitive superconducting detectors. This field includes the ultrasensitive detection of single microwave photons, arrays of large-area Josephson junctions (STJs) as XUV radiation detectors, SQUIDs as well as edge bolometers or SNSPD (superconducting nanowire single photon detectors) for safety and astronomical applications.

Wafer control

©Niklas Guenther via Canva.com

For the semiconductor industry, it is envisaged to design cryogenic systems with high performance and with large-area, uniform cooling at below 4K, i.e. e.g. down to around 1K or less.

Such systems would be very helpful for classical wafer production (silicon), and even necessary for the coming wafer production (quantum computing etc.), as the following considerations show: